Enterprise Resource Planning (ERP) systems are meant to unify operations, enhance decision-making, and streamline business processes. Yet, when poorly planned or mismanaged, these large-scale projects can lead to staggering financial losses, operational breakdowns, and damaged reputations. From Nike to National Grid, Revlon to Waste Management, high-profile ERP failures have exposed critical gaps in planning, testing, stakeholder involvement, and change management. This report explores 12 notable ERP project collapses, each offering valuable lessons for organizations navigating the complex path of digital transformation.

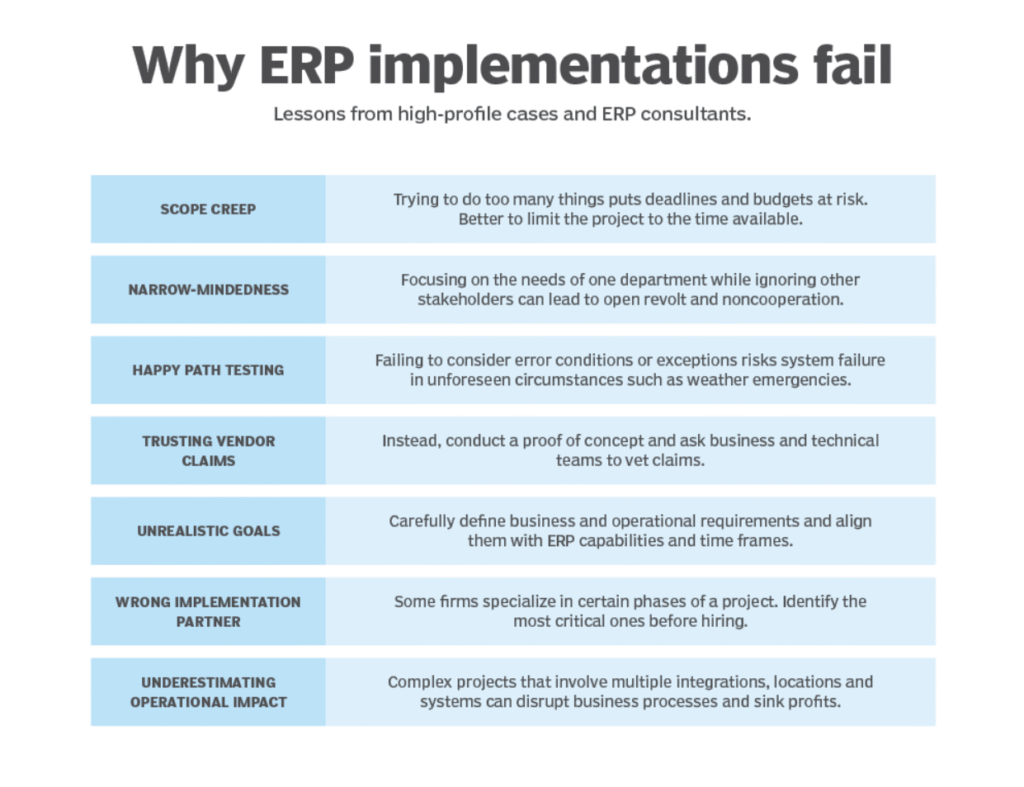

1. Nike: Unrealistic Goals

Nike’s $400 million ERP upgrade in 2000 was rushed and overambitious, leading to $100 million in lost sales and a 20% drop in stock value. The system failed to fulfill orders accurately, especially for its Air Jordan line.

Lesson: Set achievable goals, validate process alignment, and rigorously test before go-live.

2. MillerCoors: Misaligned Expertise

MillerCoors (now Molson Coors) hired HCL Technologies for ERP consolidation, but skipped crucial planning and architecture phases. The project suffered from numerous defects, eventually leading to a $100 million lawsuit.

Lesson: Choose partners with both strategic planning and execution capabilities.

3. Revlon: Ignoring Operational Readiness

Following its merger with Elizabeth Arden, Revlon tried to unify systems using SAP but lacked proper validation and SAP expertise. The flawed rollout in 2018 caused major operational disruption and a $64 million sales loss.

Lesson: Always match system readiness with operational readiness and internal capacity.

4. National Grid: Inadequate Disaster Testing

During Hurricane Sandy in 2012, National Grid’s SAP rollout failed under emergency conditions due to “happy path” testing only. Emergency processes had to be activated manually, costing the utility $585 million.

Lesson: Include disaster and stress testing scenarios before deployment.

5. Waste Management: Blind Vendor Trust

Waste Management trusted SAP’s promises of massive ROI and a fast 18-month rollout without proper internal validation. The failed project led to a $500 million lawsuit due to unfulfilled capabilities.

Lesson: Vet vendor claims with in-house expertise and conduct proof-of-concept testing.

6. University of Washington: Stakeholder Misalignment

As part of a $340 million transformation, UW’s ERP disrupted vendor payments and research funding. Finance processes were prioritized, while broader stakeholder needs were overlooked, causing internal tension.

Lesson: Engage all impacted parties—users, vendors, and partners—in planning and rollout.

7. Invacare: Cost Overruns and Poor Estimation

Medical device maker Invacare experienced major delays in its SAP upgrade, incurring costly maintenance fees and leadership changes. The board eventually replaced the CEO over project mismanagement.

Lesson: Plan realistically for timeline, cost, and partner management.

8. PG&E: Security Breach During Testing

During ERP testing in 2016, a vendor copied live PG&E data onto an unsecured network, exposing over 30,000 records online for 70 days. This resulted in public backlash and regulatory fines.

Lesson: Never test with live data—ensure strict data governance and security protocols.

9. Cover Oregon: Scope Overload

The state’s attempt to launch an online health insurance exchange and new ERP system simultaneously failed miserably. Over $300 million was spent with no functional system delivered.

Lesson: Limit project scope and align ERP goals with achievable deadlines.

10. Israel Chemicals: Narrow ERP Focus

ICL assigned its ERP project to a finance team member who lacked cross-functional insight. The system ignored manufacturing and supply chain needs, causing internal revolt and cancellation of a $500M project.

Lesson: ERP projects must include input from all critical departments—not just finance.

11. Ranpak: No Contingency Planning

Ranpak launched its ERP system in January 2022—just before the Russia-Ukraine conflict disrupted global supply chains. This unforeseen crisis delayed implementation and increased costs.

Lesson: Build contingency plans for geopolitical, market, or logistical disruptions.

12. Mission Produce: Poor Requirements & Training

After implementing a new ERP for supply chain optimization in 2022, Mission Produce faced inventory errors, missed deliveries, and confusion due to lack of clear ownership, stakeholder input, and training.

Lesson: Involve users in planning, validate partner needs, and lead with structured project governance.

Key Takeaways to Avoid ERP Failure

✅ Choose experienced ERP vendors with domain-specific success.

✅ Involve stakeholders from all functional areas in the early planning phase.

✅ Control scope and cost by avoiding frequent change requests and unrealistic expectations.

✅ Use non-production data for testing, and include worst-case scenarios in test planning.

✅ Set a realistic implementation timeline, especially when consolidating legacy systems.

✅ Train users thoroughly and communicate the change impact across the organization.

✅ Integrate clean, accurate, and validated data before going live.

Source – Computer Weekly

Leave a Reply